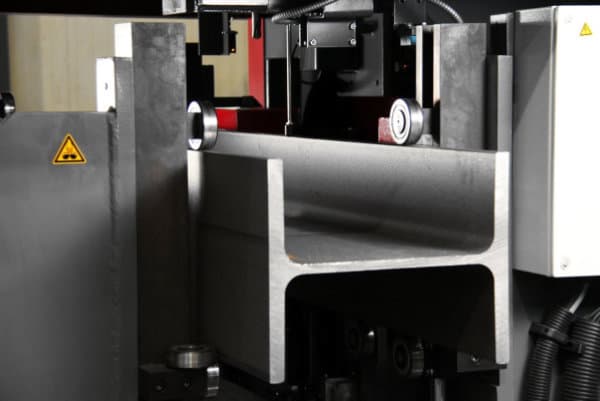

Cnc Beam Drill Line Type

GSS Machinery staff and personnel have been a tremendous support to me. Without them, I believe we wouldn't be in the position we find ourselves in in the steel fabricating markets.

Yes. Many CNC Beam Drill Line installations are available outside. The control panel and mobile platform must have adequate weather protection. We are happy to show you photos from our many outside installations.